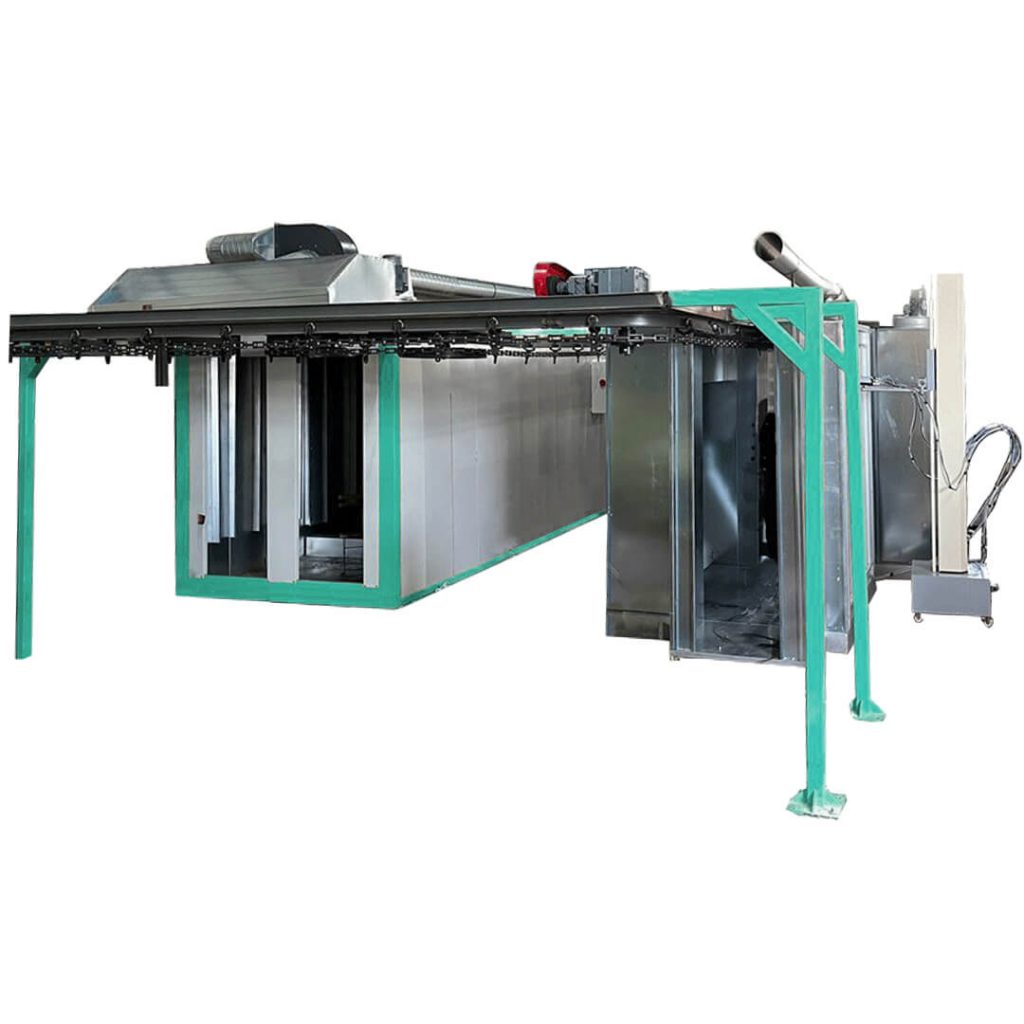

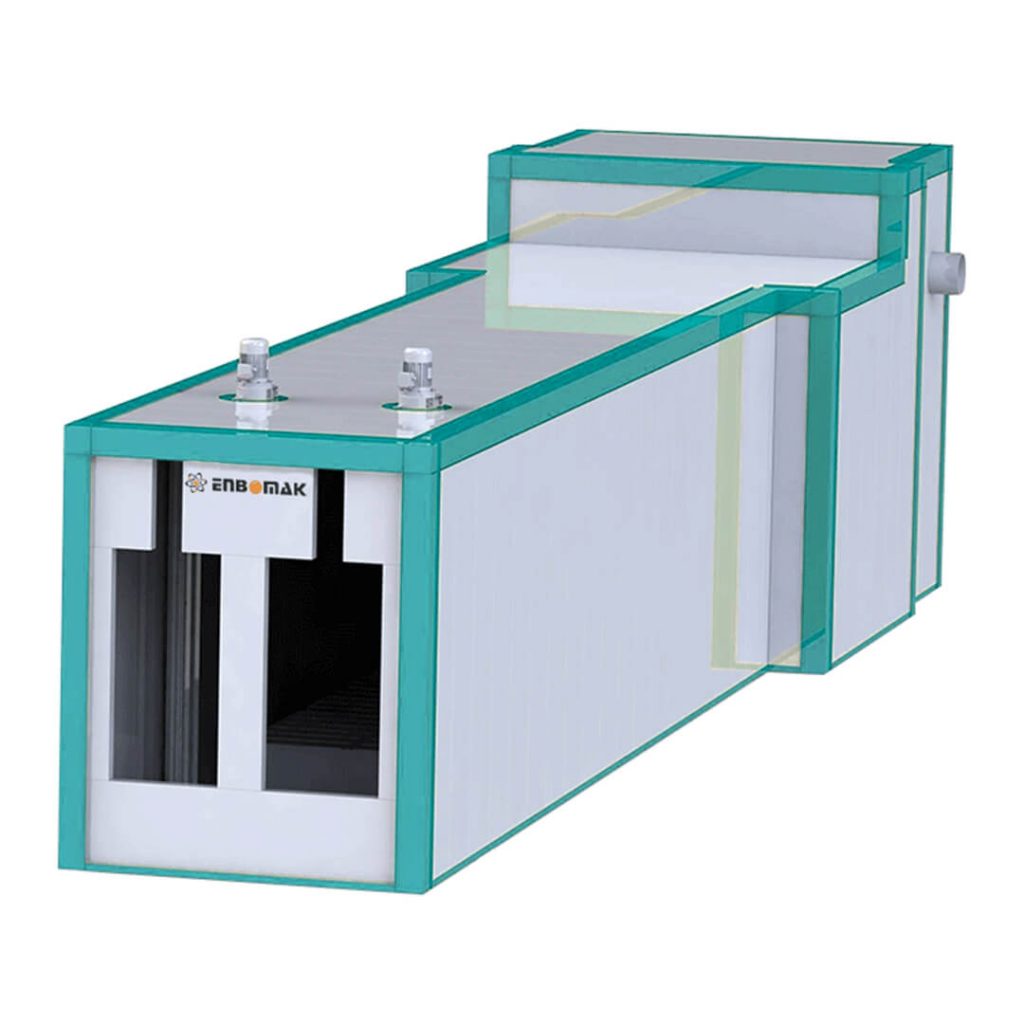

U Type Oven

Oven Construction

The body of the oven, whose technical documents are given, is made

of 1.2 mm galvanized sheet inside and 1.2 mm dkp sheet outside, on a 2.5 mm chassis,

and the outside is covered with electrostatic powder paint. It is manufactured as a sandwich with 150 mm rock wool between two walls,

and is mounted with a modular system and a

suitable mastic against high temperatures, with interlocking and screw support. It can be moved

when required. A total of two air curtain groups have been added to the inlet and outlet sections

of the oven in order to prevent heat loss.

Air Distribution Channels

The hot air prepared in the heating unit is sent into the oven with the help of air ducts made of galvanized sheet. The air ducts are made of in the way that a homogeneous air distribution can be performed in every region of the oven and can be disassembled and cleaned very simply when necessary.

Heat Control

The temperature control of the oven is done with a digital thermostat. The system is adjusted to the desired temperature and operating range via the indicator on the electrical panel system. There is a safety thermostat in case of any problem or against a heat load caused by the malfunction of the automatic control.

Heat Unit

The body of the heating unit is manufactured from 1.2 mm sheet metal outside and 1.5 mm inside, and the outside is painted with industrial paint. Its internal structure has been designed as completely welded. It is planned as burner missile type and three-pass, and the combustion chamber is made of 2 mm AISI 321 chrome nickel sheet heating pipes and 76 X 3 mm normalized boiler pipes. The heating unit operates in the most direct way and its smoke is discharged through its chimney. In this way, the danger of explosion and flashing is eliminated. The air delivery fan, which sends the heated air in the burner to the oven, is of sparse bladed and forward-curved type, and is mounted directly coupled after the dynamic and static balances are taken. Fan bearings are selected among quality brands, especially 22.200 series bearings are used.

Technical Data

Oven Type | U Type Oven |

Length | 11.000mm |

Width | 1.600mm (2.200mm Tunnel Inner Net Width) |

Height | 3.150mm (1.500mm Net Stroke) |

Heating Type | Indirect Combustion Type |

Air Curtain Aspirator | 2×4.500 M3/H 2.2 Kw 1500 RPM 2 Pieces |

Operating Temperature | 60°C – 200°C |

Temperature Control | Digital Thermostat |

Building Material | External 1.2 Mm Dkp, Internal 1.2 Mm Galvanized Sheet |

Insulation Material | 150 Mm Stone Wool (Ρ=53 Kg/M³) |

Oven Heat Unit Technical Data

Heating Unit | 1 Piece |

Heating Energy | Natural Gas |

Circulating Air | 12.000 M3/H X 2 Pieces |

Engine Power | 5.5 Kw X 2 Pieces |

Heating Capacity | Between 250.000 – 300.000 Kcal/H |

Burner | Flam Or Üret Brand |

Insulation | 150 Mm Rock Wool |