Box Type Ovens

Box type ovens are used in wet paint applications in industrial facilities. During these applications, these ovens take part in the process of cooking the paint. These furnaces are produced with electric resistance, liquid or gas fuel operation options. In these ovens, the air heats up and is given back into the oven thanks to the fan. These furnaces can be used in paint applications at high temperatures up to 250 degrees.

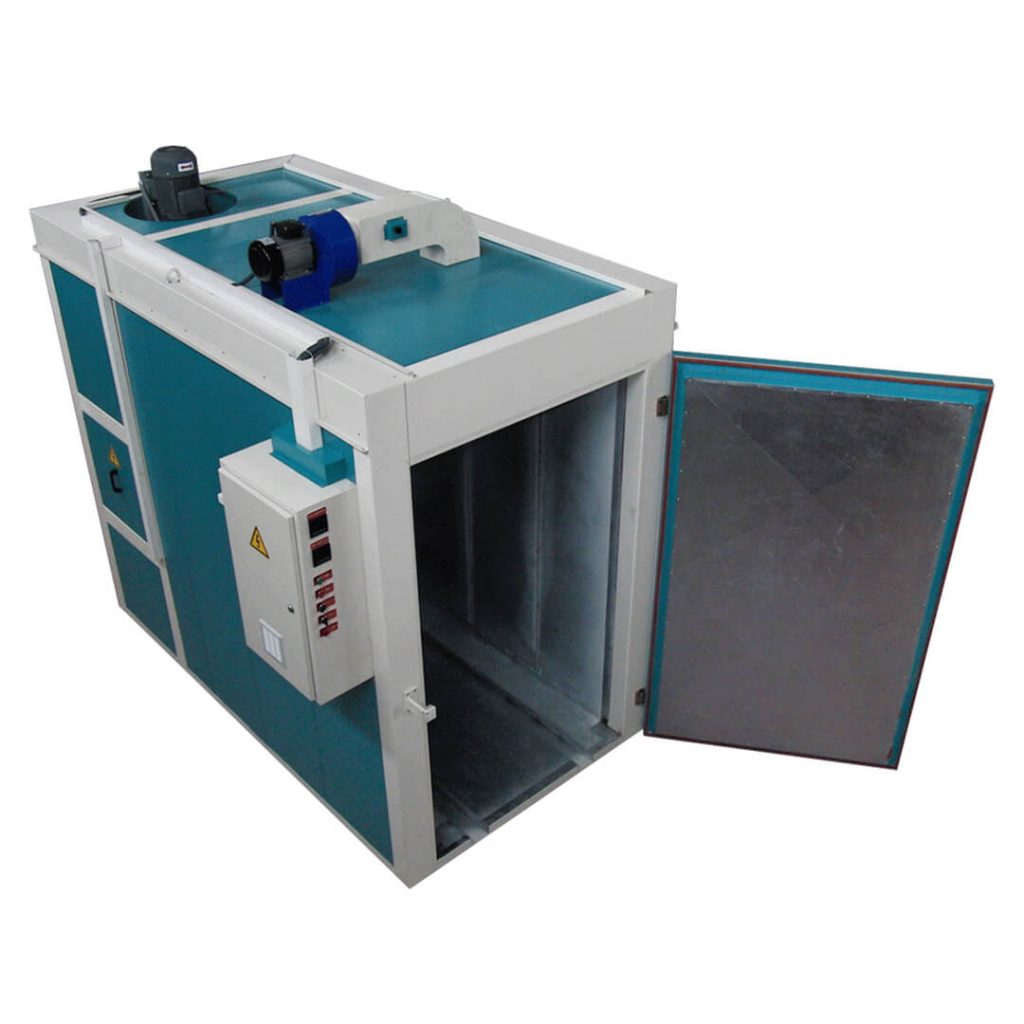

The ovens used in paint applications are referred to by this name because of the way they are called. These ovens get this name because they have a box-like design. The usage sector is also very wide and can take part in difficult conditions. Box type oven is in high demand for quality paint applications.

What are the Features of Box Type Oven?

Box Type Oven Usage Areas

Box type oven usage areas can be counted as many of the industrial facilities. You can see box type ovens in powder enamel plant or powder coating application plants. In summary, box type ovens are used in every field and industrial branch where powder coating applications will be made. Although these ovens are produced as standard, they are also produced on a project basis.

We first inspect your plants for your powder coating applications. Then we make special production for your needs. First, we determine your demands and needs. After this process, we immediately make project-based production. Our teams support you for box type ovens in all matters such as installation, maintenance and repair.

Box Type Oven Prices

Box type ovens are among the most important ovens that you will encounter in powder coating applications . These ovens are produced in different sizes and with different characteristics. We give you a special price on a project basis for box type oven prices. First of all, we create the production plan after the free discovery service we do in your facilities. In this process, we also provide delivery time and price quote for you.

You can learn all the details you are curious about box type oven prices from our company. You can get support from our company for high quality and high performance box type ovens. We always serve you for high quality and long-lasting oven varieties. We always support you in the production and assembly processes.

Box Type Ovens

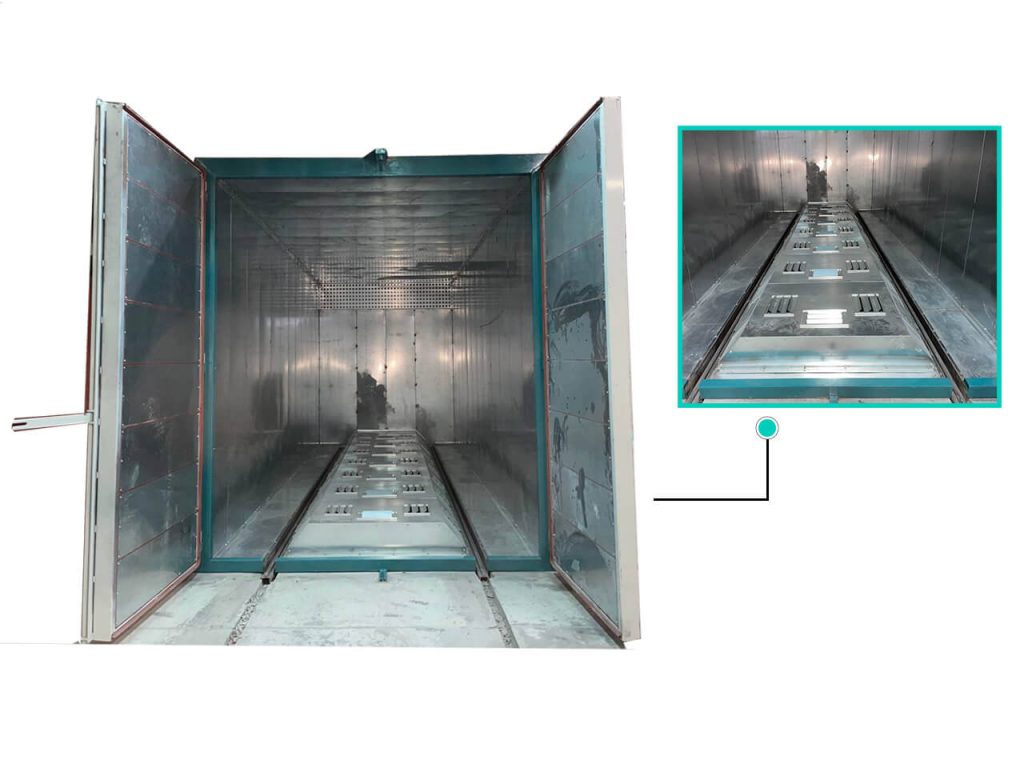

Our box type powder ovens, box type powder coating ovens are designed to minimize heat losses. It has carriage entrance from one side. There are hinged type doors at the front of the ovens. Material inlets and outlets are provided into the furnace through these doors. Fixed channels are laid at the bottom of the oven, and the oven inner carriers are moved on these channels. Our double door box type ovens consist of sandwich type interlocking panels.

The inside of the oven is made of galvanized sheet, and the outside is made of powder-coated dkp sheet. 300ºC resistant silicone is used at the joints of the wall panels. Oven side walls are insulated with 150 mm thick and 70 Kg/M³ rock wool. Combustion chamber area is insulated with 90 Kg/M³ rock wool with a total thickness of 150 mm. The circulation fan is of direct coupled heat resistant insulated type suitable for operation at 250ºC. There are air channels that distribute the air evenly and homogeneously inside the oven, and air blowing vents that can be adjusted as desired. The system, which works according to the closed circuit air circulation principle, reaches the desired temperature in a short time. Temperature control is provided by a digital thermostat and the temperature is adjusted to the desired degree and controlled. The thermoblock is mounted at the back of the oven and has the capacity to increase the temperature of the oven to 250ºC. Combustion cell thermoblock is made of high temperature resistant AISI 321 quality 3mm stainless steel, and pipe bundles are made of 76×3 steel drawn boiler pipes.

Technicial Specifications

INSIDE DIMENSIONS

Width (Mm) 1.500

Length (Mm) 2.000

Height (Mm) 2.000

External Dimensions

Width 1.800

Length 3.000

Height 2.300

Material

Panels 1,2mm Dkp And Galvanized Sheet

Air Duct 2mm Galvanized Sheet

Chassis 3mm Dkp Sheet