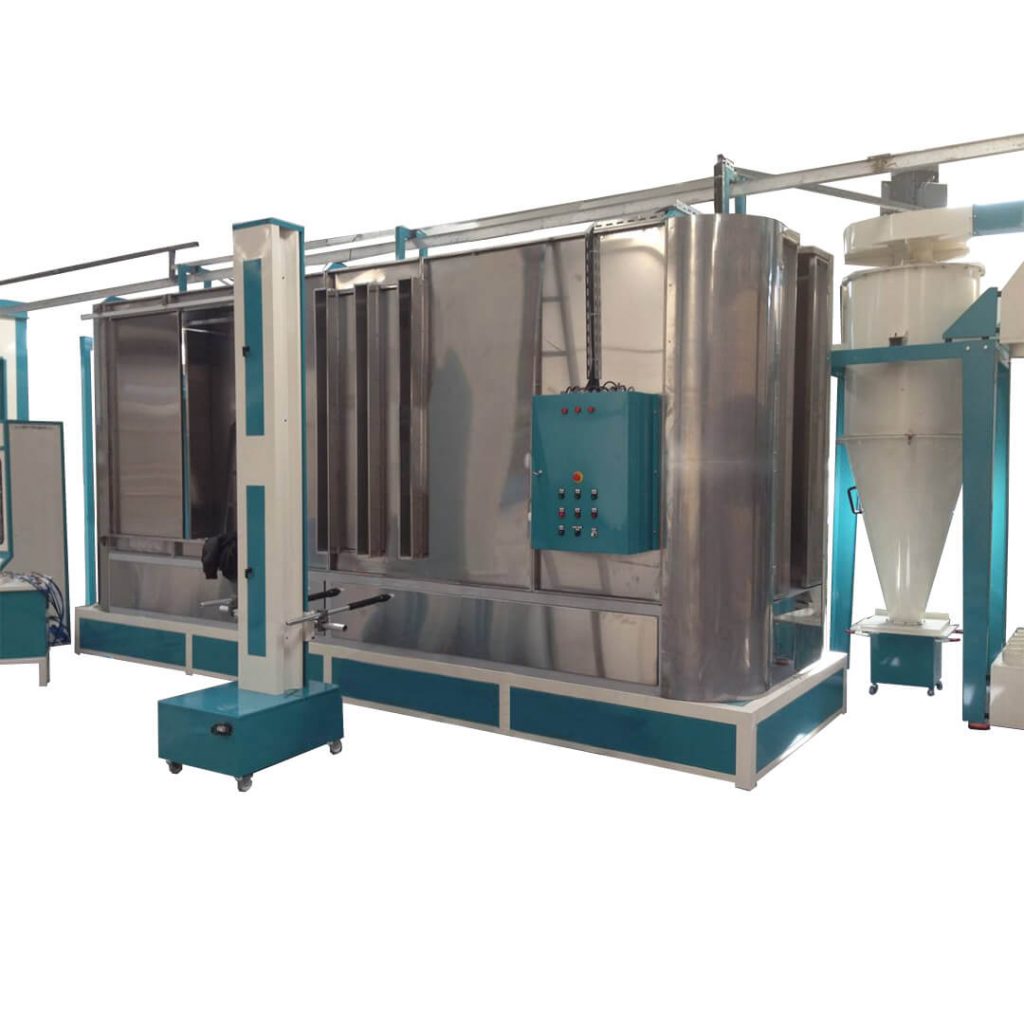

Powder Paint Oven (Tunnel Type)

Oven Construction

Air Distribution Channels

Heat Control

Technical Data

Oven Type | Tunnel Type |

Length | 24.000mm Outside (24.000 Mm Inside Net) |

Width | 1.300mm Outsite (1.000 Mm Inside Net) |

Height | 3.150mm Outside (1500 Mm Net Strong) |

| Heating Type | Indirect Combustion Type |

Air Curtain Introduction | 1×4.500 M3/H 2.2 Kw 1500 D/Min 1 Piece Input |

Air Curtain Output | 1×5.500 M3/H 3 Kw 1500 D/Dak 1 Piece Output |

Operating Temperature | 60°C – 220°C |

Temperature Control | Digital Thermostat |

Building Material | External 1.5 Mm Dkp, Internal 1.2 Mm Galvanized Sheet |

Insulation Material | 150 Mm Stone Wool (Ρ=70 Kg/M³) |

Tunnel Oven Heat Unit Technical Data

Heating Unit | 1 Piece |

Building Material | AISI 310 Quality Stainless (3 mm Sheet Parts) |

Thermoblock Pipe Bundles | AISI 304 Quality Æ 76 X 3 Mm The First Turning Part |

Thermoblock Pipe Bundles | Æ 76 X 3.2 Mm Drawing Steel The Second Turn |

Heating Energy | Natural Gas Circulation Air: 20.000 M3/H X 2 Pieces |

Engine Power | 7.5 Kw X 2 Pieces |

Heating Capacity | Between 200.000 – 500.000 Kcal/H |

Burner | Flam Brand (1 Piece) |

Fuel Consumption | Between 34 Min.– 60 Max. M3/H |

Insulation | 150 Mm Rock Wool |