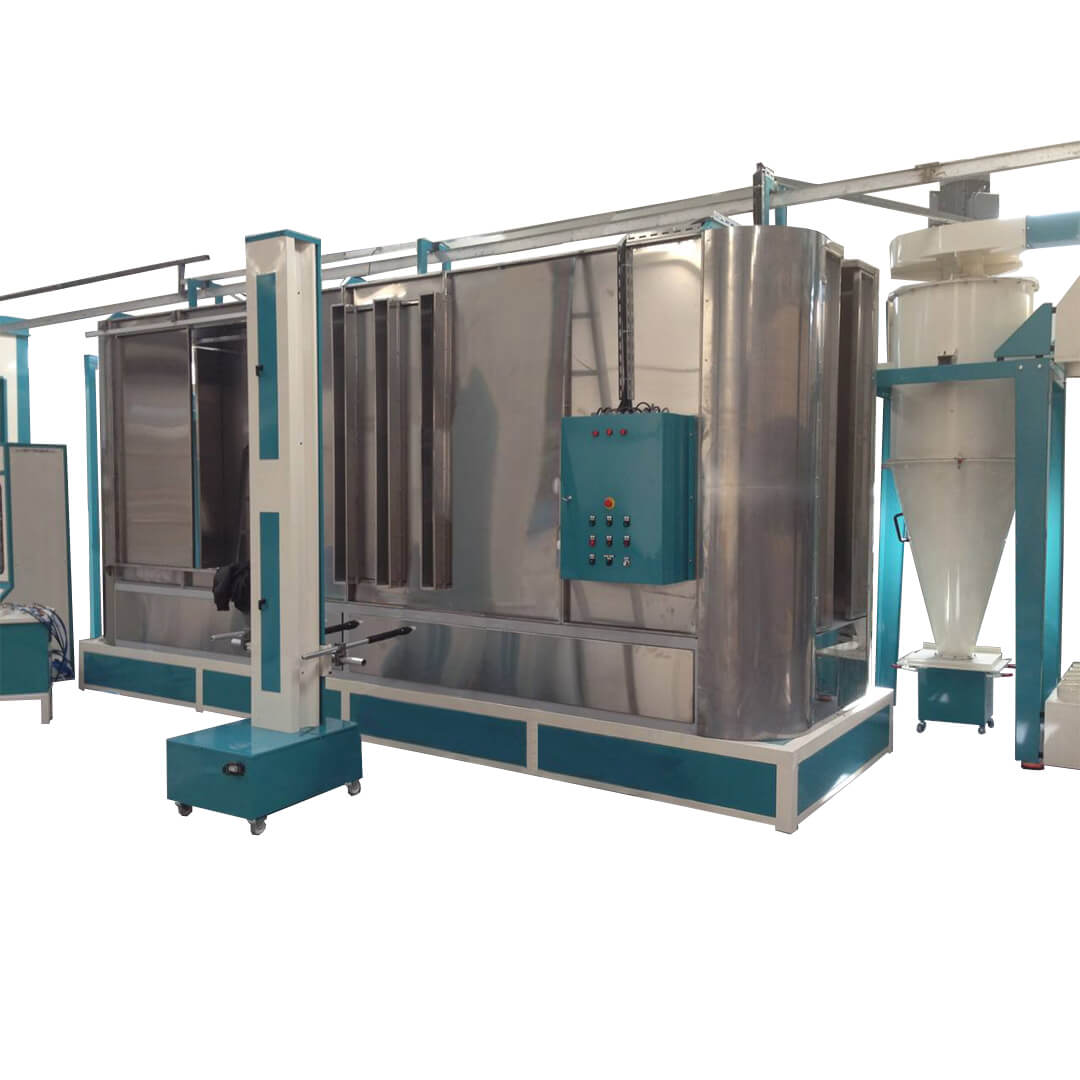

Tunnel Type Furnaces

Tunnel type ovens are ovens designed with two sides open and heated centrally. In these devices, there is only one heat source in the middle section, and after the material is slowly heated, the powder coating process is done and then cooling on the inside. These furnaces are used in conveyor plants where powder coating applications are made. When the paint is baked in the oven, it is produced with diesel or gas burners.

Tunnel type ovens work with the system of heating the air in the fan and then giving it back to the oven. These furnaces are designed in conveyor paint plants taking into account plant layout and process. Our company produces special tunnel type ovens for all your needs.

Tunnel Type Furnace Technical Specifications

- Tunnel type furnaces are cyclothermic furnaces with conveyor systems produced from large These ovens are used in powder coating applications.

- Tunnel type oven types are produced as standard in 2.5 and 3 meter band width. We produce in the sizes you want between 14 m and 36 m for your special orders.

- We produce tunnel type furnaces from durable materials. The bodywork is made of stainless material and can be used at high temperatures.

- You can make different powder coating applications with the 3-phase cooking system in tunnel ovens.

- Thanks to the PLC control panel, powder coating applications are much more practical.

- Quality paint applications can be made with cooking balance. There are extra circulation fans to achieve low fuel consumption.

- With the hydraulic belt centering feature, the application can be made in a better quality way.

- The automatic belt tensioning system makes the working process more comfortable.

- For tunnel type ovens, you can adjust the lower and upper temperatures of the cooking chamber as you like.

- At the oven outlet, all models have a standard water spray system.

In addition to all these, we produce tunnel type ovens with the features you want.

How Do Tunnel Type Furnaces Work?

Tunnel-type furnaces have a simple principle of operation. First of all, the materials to be painted are hung on the conveyor. Then from here it enters the oven. Then it exits from the same surface. The painted material makes a U-turn in the oven and then returns.

Energy savings can be maximized in heating processes with low volumes in tunnel type furnaces. The dimensions and capacities of the oven vary. Features such as paint cooking and drying time, the length of the parts planned to be painted are effective in this. Tunnel type ovens are used in powder coating baking and drying after washing. Powder coating baking ovens in classic air circulation ovens a process is completed in 17-18 minutes. In gas-type infrared ovens, the process is performed between 5-10 minutes. Powder baking ovens operate at 200 degrees.

Tunnel Type Furnaces Usage Areas

Tunnel type ovens work in the form of application during baking by hanging the pieces to be applied to the oven conveyor to be powder painted. After the process of hanging the part on the conveyor, the part is thickened and cooking or drying is done during the departure at a certain speed according to the square meter forehead. Air curtains in the inlet and outlet process and specially designed air crushers eliminate heat loss. Tunnel type ovens are used in industrial enterprises with high capacity. It has use in industries such as agricultural machinery, aluminum industry, automotive and spare parts, white goods and construction.

Tunnel Type Oven Prices

Tunnel type oven prices vary according to the technical specifications, size, brand and design of the product. We produce these ovens on a project basis according to the area and needs in industrial facilities. Therefore, after preliminary examination and discovery, we offer a price quote to our customers.