Manual Cabins

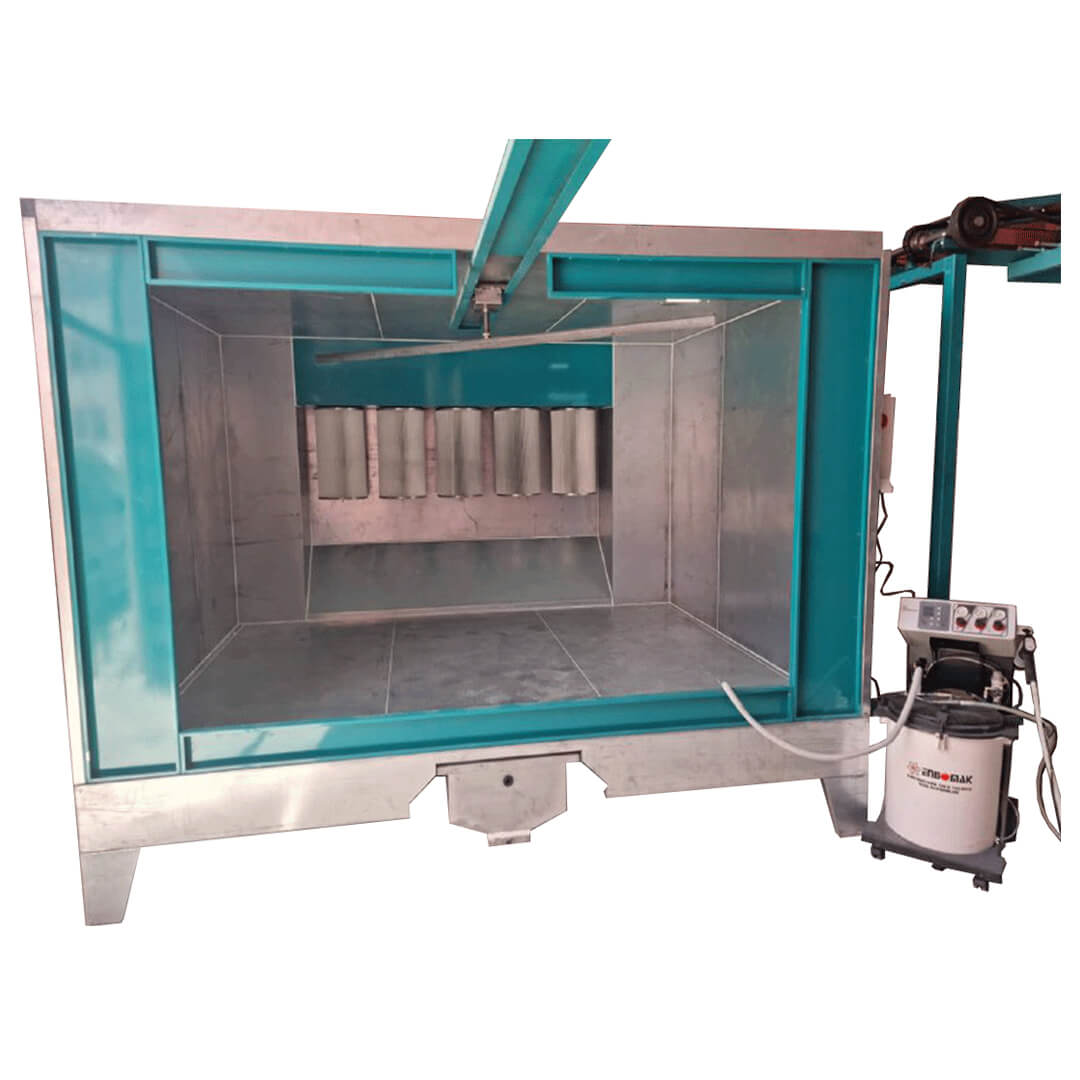

The areas where powder coating applications are made are the cabins. When the powder coating process is done in the ovens, it is done automatically. If a manual painting process is to be done with powder coating devices, manual cabinets are used. These booths are involved in spray painting processes, which are a dry coating system. The material planned to be painted in the cabin is manually sprayed with a powder coating device.

During application, powder coating particles do not adhere to the painted part. Thanks to the air flow from the intake fan, it is filtered inside the cabin and the particles are trapped inside. In this application the first step for the recycling process is ending. The powder coating grains accumulated on the filters are poured into the bottom of the cabinet and then sieved through. It can then be reused with the powder coating injector. In this way, the waste of powder coating is also prevented.

Manual powder coating booths are useful products that make the painting process practical. These products are made of stainless steel sheet and halva material. Every part of the products whose parts are disassembled is bolted and can be assembled immediately. These products are specially designed for the one-sided painting process.

Manual Cabinets Technical Specifications

- Manual cabinets are made of sheet metal or galvanized stainless materials. Production is realized from 1.5 mm and 2 mm DKP sheet.

- In manual cabinets, painting is done from one side.

- The manual cabinets feature cartridge recovery. Polyester cartridge filters are used for this feature.

- In manual cabinets with compact design, small batch quantities can also be painted economically.

- These products have galvanised coating and steel construction design.

- Maintenance is also extremely easy in the cabins with practical design.

- With Ex-proof lighting in the cabins, powder coating applications can be made more practically.

- Manual cabinets have CE certified control panels. In this way, the desired adjustments and follow-up process can be easily made.

- The pneumatic vibration screen integrated into the control panel also attracts attention.

- Thanks to the automatic blasting function in the products, a long-lasting and reliable air flow is ensured.

- In manual powder coating booths, chimneys with silencer filters eliminate the noise of operation.

- Stainless steel panels are effective in making the product more durable.

Advantages of Manual Cabin Use

Manual cabinets are systems where powder coating applications can be easily made. Our company produces manual cabins for all kinds of needs. Specially designed manual cab models offer maximum comfort to operators. It also helps to achieve the highest performance in paint applications.

Manual cabins have a recovery feature with durable construction. Thanks to these features, low operating costs arise. Thanks to these products, which keep the dust in the cabin, the painting processes in your business are both clean and safe. In areas where there are powder coating booths, your facilities will remain clean and you will take occupational safety measures in a safe working environment.

Manual Cabin Prices

Manual cabinets ensure that powder coating applications are carried out safely, flawlessly and in a short time. Thanks to the spray technique with manual powder coating guns on the application surfaces, a perfect painting process is made. Since the manual cabin is processed, although the material usage is minimal, there is superior performance. At the same time, these cabinets make the working environment tidy and reliable.

Manual cabin prices vary according to the material, technical specifications, functions and dimensions of the product. We produce manual cabinets that meet every budget and need for you. We offer production and free assembly services for our customers who want to order cabin. You can compare manual cabin prices by visiting us.